Sales & Operations Planning

SALES AND OPERATIONS PLANNING IN ALIGNMENT WITH CORPORATE OBJECTIVES

Sales and Operations planning, in simple terms, is a process that aims to integrate demand and supply in a manner that is aligned with business objectives.

The breadth of its scope is one that makes it complex as it involves the integration of “sales, marketing, new product launch, manufacturing, and distribution into a single plan"[1]. The complexity of bridging the gap between supply and demand had been steadily growing since S&OP was introduced in the 80s, but in recent times there has been a growth-spurt in complexity as now, more than ever before, there is a greater need for customer-centricity and market focus (that is, for processes to be “outside-in” rather than “inside-out” or supply focused).

THE MATURE S&OP PROCESS: OUTSIDE-IN

An outside-in approach begins with an assessment of the needs of the market and then requires designing supply chain processes to achieve a strategic fit. What constitutes a fit might vary by product or customer segments. For example, the focus for certain customers might be cost efficiency, and for certain others, it might be service excellence. Therefore, designing differentiated processes and metrics, starting with desired business outcomes (aligned with the customer value proposition) is one of the main challenges for a mature S&OP process.

Minimum attributes in a mature process

Although definitions and characterizations differ in their details for the stages of S&OP maturity, there is a broad alignment regarding certain minimum attributes a mature process should possess. It includes: instituting a monthly planning cycle that is cross-functional in nature, integrating finance in the process (a mature process is not merely volumetric), a long-term planning focus (not just chasing end-of-quarter targets), and scenario modelling to explore multiple perspectives when challenged to reconcile supply and demand.

A case study with key characteristics

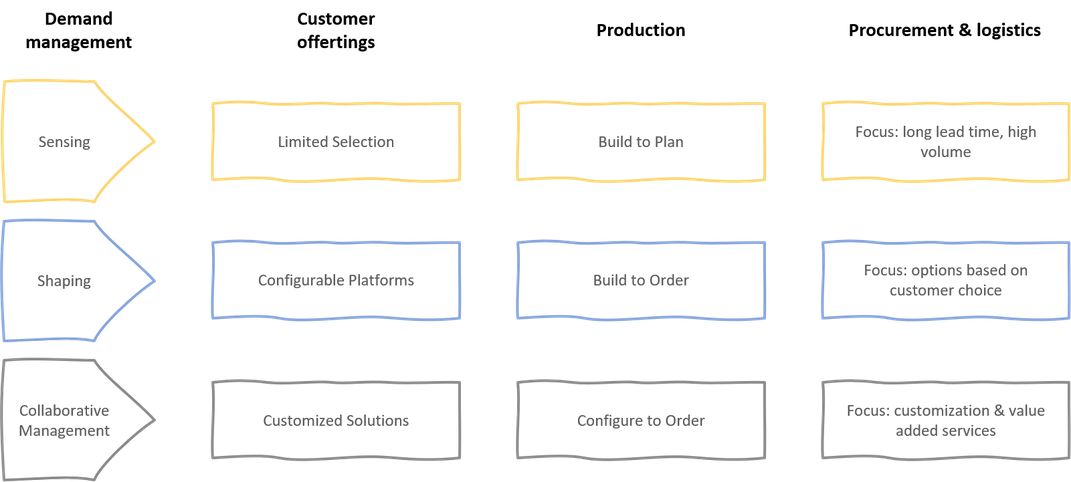

A case study of a company in the consumer electronics industry [2] is summarized in Figure 1 as an example of “what good looks like”. It embodies some of the key characteristics outlined in the previous paragraph.

The company aligned its supply chain capabilities (in terms of production, procurement, and logistics processes) according to its go-to-market strategies, which were determined by customer offerings that fell into three streams or segments:

- Products that were built to plan

- Products built to order based on options chosen by customers

- Products that can be freely customized that were configured-to-order

Sensing, Shaping, Collaboration

The demand management approach was accordingly tailored to the different streams as the focus was sensing for segment one (as products are built to stock), shaping for segment two (to incentivize customers towards profitable products), and collaboration for segment three (where customers and supply chain stakeholders “jointly” search for solutions). The demand management strategy subsequently drove the orientation of internal supply chain capabilities to ensure a tight fit for an overall mature S&OP process.

SUITABLE TOOLS FOR AN END-TO-END S&OP PROCESS

The shift in the focus of the S&OP process, from a functional orientation to truly cross-functional integration, also explains the importance given in recent years to technology support, or the lack thereof. Until as recently as the turn of the previous decade, there were no tools available that could support an end-to-end S&OP process and companies had to resort to homegrown solutions or Excel.

However, with the introduction of SAP’s S&OP planning solution and solutions from other vendors as well, companies were able to bridge the gap between process requirements for a mature S&OP process and technological capabilities along multiple dimensions: connecting strategic, tactical, and operational plans; connecting volumetric and value-based data; connecting different functions across the organization—of particular note here is the integration of finance into the overall process.

Integrated Business Planning IBP

As soon as S&OP solutions started to get introduced, process requirements began to outpace capabilities of planning technologies with the onset of the digital revolution. Increasingly, companies are seeking to further grow in maturity by extending horizontal integration to include both buy and sell-side markets and orchestrate demand by using new innovations in digital technologies.

The changes are significant enough to have warranted a new term “Integrated Business Planning”, which seems to be the direction in which S&OP is headed in the foreseeable future—both from a process maturity and technology-capability perspective.

You can find out more about the technological solutions for "Integrated Business Planning" on our page "SCM Solutions" and in particular under "SAP IBP".

[1] Simchi-Levi, D., Kaminsky, P. and Simchi-Levi, E. (2008), Designing and managing the supply chain: Concepts, strategies, and case studies / David Simchi-Levi, Philip Kaminsky, Edith Simchi-Levi, McGraw-Hill/Irwin series operations and decision sciences, 3rd ed., McGraw-Hill/Irwin, Boston, MA, London.

[2] Stank, T., 2016. Integrating Sales And Operations To Create Higher Value For Customers. [online] MIT Sloan Management Review. Available at: <https://sloanreview.mit.edu/article/integrating-sales-and-operations-to-create-higher-value-for-customers/> [Accessed 11 May 2020].

[3] Stank, T., 2016. Integrating Sales And Operations To Create Higher Value For Customers. [online] MIT Sloan Management Review. Available at: <https://sloanreview.mit.edu/article/integrating-sales-and-operations-to-create-higher-value-for-customers/> [Accessed 11 May 2020].